GTE / Products / Turbine - Compressor Water Wash and Cleaning Systems

GTE has designed and patented a highly atomized delivery, water wash technology that was initially developed to clean commercial and military aircraft engines, but today this technology has been expanded to serve industrial gas turbines in addition to aviation applications.

These water wash systems are not a high pressure spray system as would be the case for a pressure washer, rather they rely on the volume and delivery pressure with full pressure drop across its spray nozzles. This provides the optimal droplet momentum for cleaning, while atomizing the water droplets.

The technology offered by GTE has accumulated over 20 years of aviation water wash experience and over 20 million operating hours on nearly 800 units in the industrial gas turbine business. The collective experience has provided the foundation for an expanding line of compressor cleaning systems on stationary and mobile gas turbines.

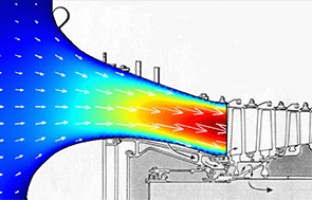

Gas turbine compressors consume approximately 60% of the overall cycle energy during operation. This cycle consumes large quantities of air and although this air is filtered, small quantities of dust, aerosols and water pass through the filters and deposit on the blades. These deposits decrease the air flow of the compressor and the overall performance of the gas turbine.

Compressor cleanliness can be maintained using a routine program of water washing. There are two water wash methods performed on gas turbines: offline and online. Offline is conducted with the gas turbine in a cooled state using cranking speed, while an online process is conducted with the machine at operating temperature and uses water only. Both operations use highly atomized water spray patterns designed to completely enter the compressor core. The offline process cleans the entire core and recovers lost performance, while the online cleans the early stages and extends the time to provide peak availability and higher average power output.

The patented GTE highly atomized compressor wash system will offer the gas turbine operator the following improvements:

- Availability: ~ 2 %

- Performance/Output: ~ 3 %

- Heat Rate: ~ 1 %

- Payback: a few months

The GTE compressor wash system is proven on more than 1000 stationary gas turbines, includes models from GE, Siemens, Rolls-Royce, Pratt & Whitney and others. The experience totals more than 30 million hours of gas turbine running time.

Contact our team today to see the benefits of a GTE advanced water wash technology solution.